Chemical Resistant Roof Mount Air Conditioners & Heat Pumps

Bebco provides a broad range of optional features to satisfy your exact requirements!

Optional Features

UNIT CONTROLS

- Basic Controls

– For Corrosive Environments in Unclassified Areas - Eco Cool™ & Eco Pump™ Controls

– For Declassified Spaces in Classified Areas - Smart Cool™ & Smart Pump™ Controls

– For Classified Spaces in Unclassified & Classified Areas

SAFETY & SECURITY FEATURES

- Alarm Contacts & Emergency Unit Shutdown Circuit

– Advanced safety features for critical applications - Temperature Setpoint Adjustment Lockout Options

– Limits Room Temperature Adjustment to Authorized Personnel

CORROSION RESISTANCE ENHANCEMENTS

- Refrigerant System Coil & Tubing Coatings

– Significantly extends refrigerant system lifespan with 5 Year Warranty! - Spray or Powder Coated Case & Chassis Finishes

– Significantly extends Unit lifespan in mild to highly corrosive environments

Scroll down or contact a Bebco Sales Associate to learn more…

MORE INFORMATION

Click any image to enlarge…

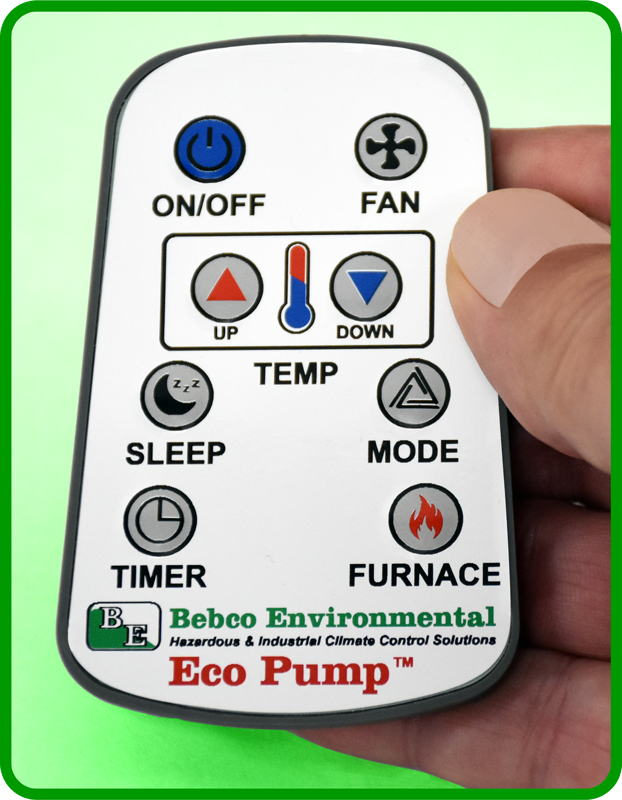

Basic Controls

– for Corrosive Environments in Unclassified Areas

-

Unit On/Off and Fan Auto/Speed Controls

-

Room Heating and Cooling Setpoints

-

Digital Room Temperature/Setting Display

-

Mode Control and Shut-Off Delay Timer

Basic Control Interfaces are primarily intended for use in Units that must withstand mild to highly corrosion environments in unclassified areas.

Key features include a digital temperature display and control buttons which permit easy adjustment of fan speeds and operating modes. Other control features include delay and sleep timers.

This very economical control system is ideal for rooms or buildings where no flammable or ignitable substances are stored or processed. Typical applications include Guard Shacks, Crane Cabins, Data Loggers, Analyzer Buildings, Portable Laboratories, Break Rooms, Locker Rooms, Shower Rooms and Restrooms.

Adjustments:

- Power On & Off

- Unit Fan Speed

- Operating Mode

- Unit Start/Stop Delay Timer

- Temperature & Timer Settings

Status Displays:

- Room Temperature

- Cooling Temperature Set Point

- Heating Temperature Set Point *

- Start & Stop Delay Timer Settings

- Auto, High, Medium & Low Fan Speeds

- Cool, Dry, Heat & Fan Operating Modes

* Applies to RHP Units featuring Basic Controls

As a very exclusive feature offered only by Bebco, all Units featuring our Basic Controls are provided with a remote control. This remote control supplements the grille or wall mounted digital control interface to control most Unit functions and adjust room temperature!

And no worries, if you ever break or loose your remote, the first replacement is on us!

Basic Controls are economical control solutions for Units serving buildings and rooms located in refineries, chemical manufacturing plants, offshore drilling rigs and other industrial facilities in unclassified locations.

Please note that Basic Controls are third-party listed by the original unit manufacturer and the final decision regarding their suitability for any specific application rests with the AHJ or Facility Safety Management Authorities.

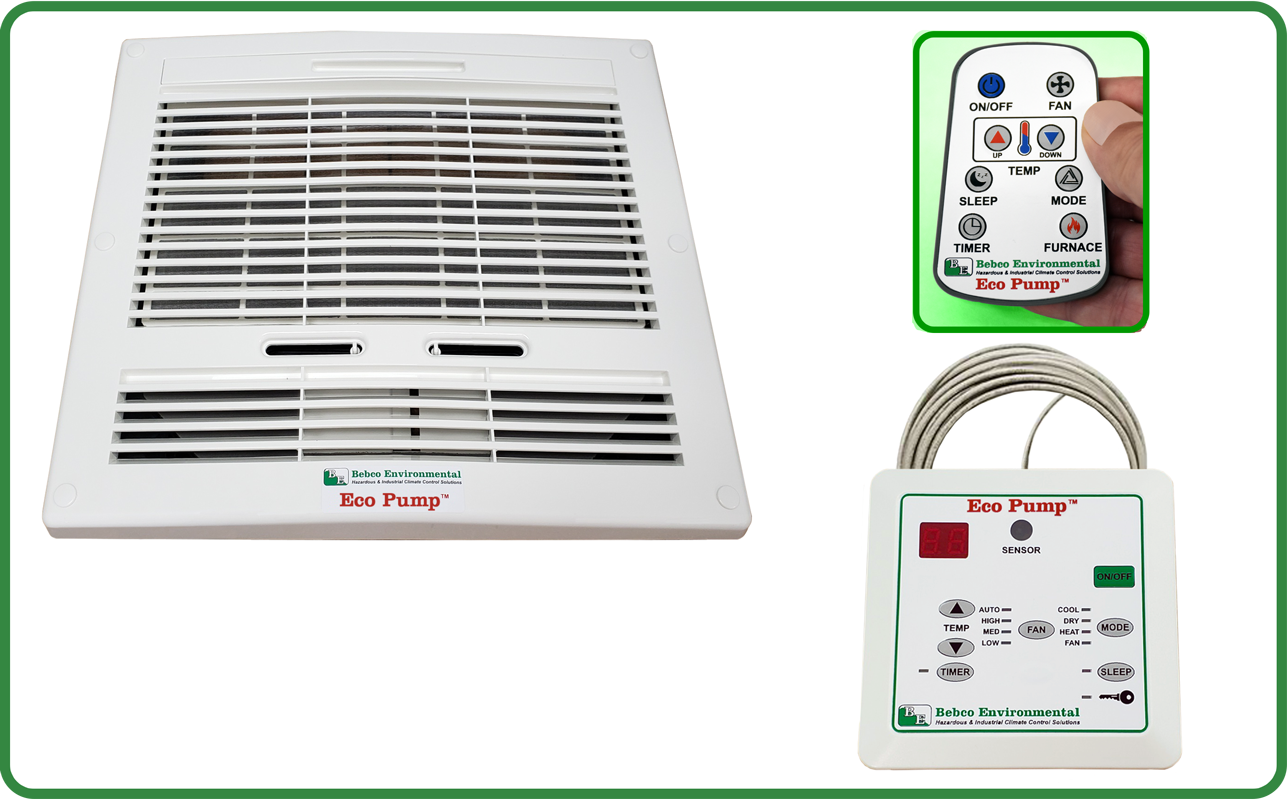

Eco Cool™ & Eco Pump™ Controls

– for Pressurized or Unclassified Rooms or Buildings in Hazardous Areas

-

Unit On/Off and Fan Auto/Speed Controls

-

Room Heating and Cooling Setpoints

-

Digital Room Temperature/Setting Display

-

Mode Control and Shut-Off Delay Timer

Integrated Eco Cool™ and Eco Pump™ Control Interfaces are provided with Bebco Model RAC and RHP Roof Mount Air Conditioners and Heat Pumps when selected.

Key features include a digital temperature display and control buttons which permit easy adjustment of fan speeds and operating modes. Other control features include delay and sleep timers.

This economical control system is ideal for spaces that do not contain an internal source of flammable gas or vapor. Typical applications include Guard Shacks, Crane Cabins, Data Loggers, Analyzer Buildings, Portable Laboratories, Break Rooms, Locker Rooms, Shower Rooms and Restrooms.

Adjustments:

- Power On & Off

- Unit Fan Speed

- Operating Mode

- Unit Start/Stop Delay Timer

- Temperature & Timer Settings

Status Displays:

- Room Temperature

- Cooling Temperature Set Point

- Heating Temperature Set Point *

- Start & Stop Delay Timer Settings

- Auto, High, Medium & Low Fan Speeds

- Cool, Dry, Heat & Fan Operating Modes

* Applies to RHP Units featuring Eco Pump™ Controls

All Bebco Eco Cool™ and Eco Pump™ Controls are provided with remote controls. This remote control supplements the grille or wall mounted digital control interface to control most Unit functions and adjust room temperature!

And no worries, if you ever break or loose your remote, the first replacement is on us!

As our trademark names imply, Bebco Units with Eco Cool™ or Eco Pump™ Controls are economical environmental control solutions for Units serving buildings and rooms located in refineries, chemical manufacturing plants, offshore drilling rigs and other industrial facilities with hazardous classified locations.

Please note that while Bebco Units with Eco Cool™ or Eco Pump™ Controls are ETL listed and feature prominent labels indicating that buildings or rooms must be pressurized, the final decision regarding their suitability for any specific application rests with the AHJ or Facility Safety Management Authorities.

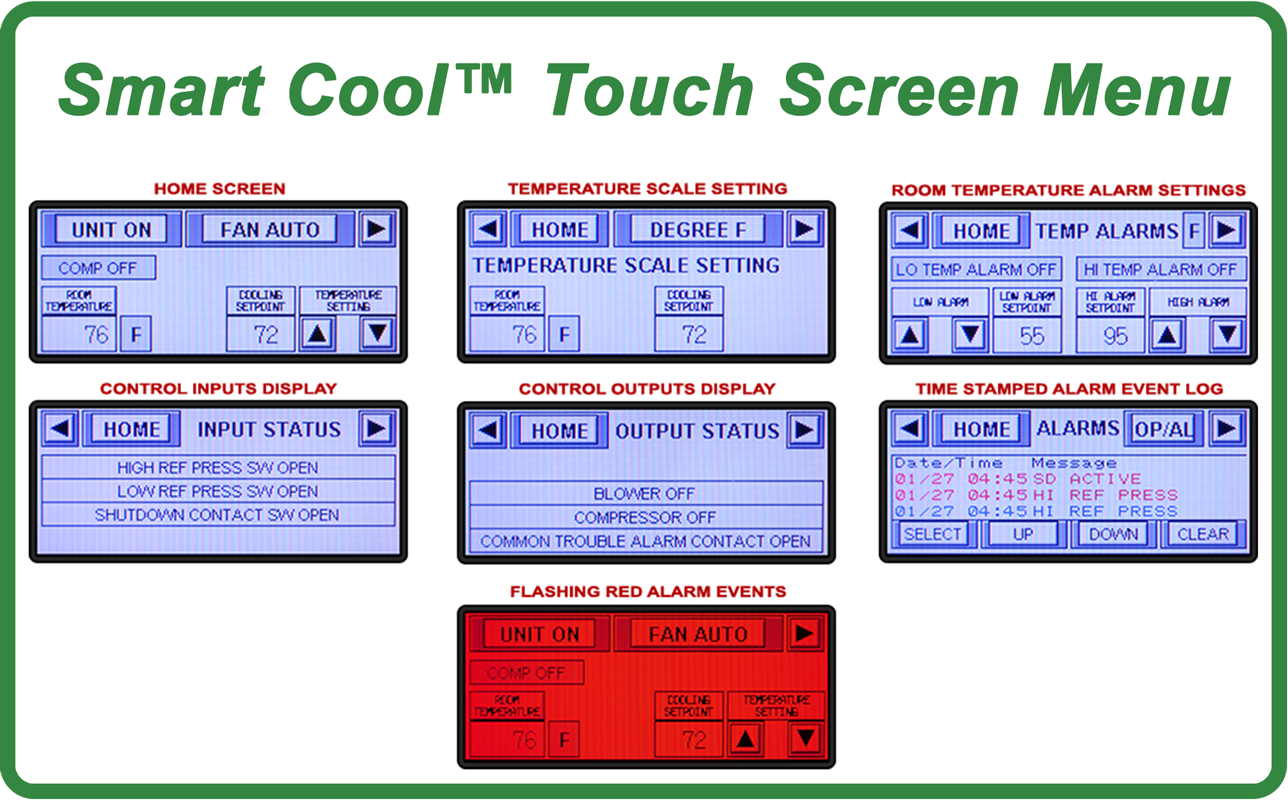

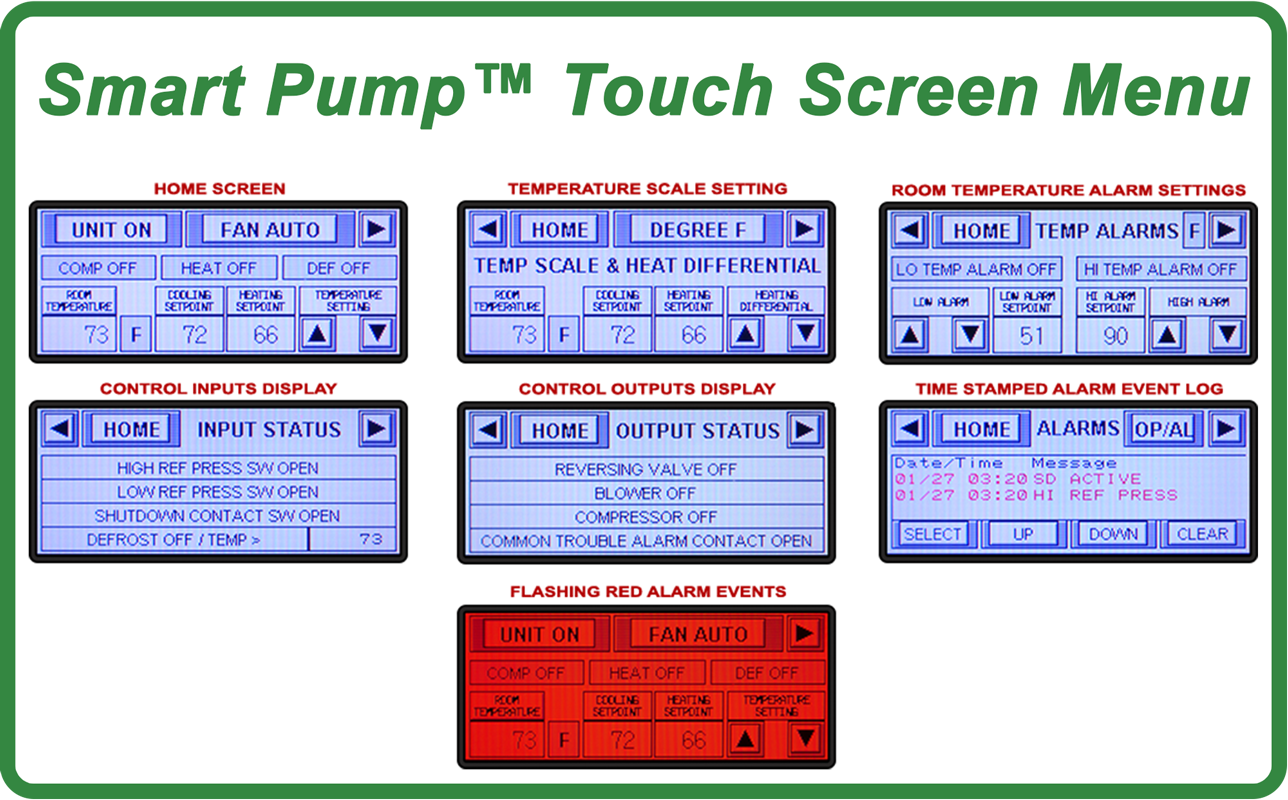

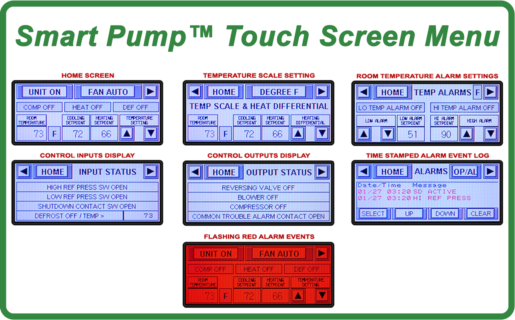

Smart Cool™ & Smart Pump™ Controls

– for Advanced Control Features or Classified Rooms or Buildings in Hazardous Areas

-

Touchscreen Controls

-

Room Cooling and Heating Differential Setpoints

-

Low and High Room Temperature Alarm Settings and Contacts

-

Advanced Diagnostics, Input and Output Status and Alarm Event Log Screens

Integrated Smart Cool™ and Smart Pump™ Control Interfaces are provided with Bebco Model RAC and RHP Roof Mount Air Conditioners and Heat Pumps when selected. Key features include a touch-screen, to permit easy adjustment and provide complete diagnostics. A flashing alarm screen and remote alarm device contacts also annunciate critical performance issues!

This advanced control system is ideal for any spaces containing an internal source of flammable gas or vapor or any spaces that feature critical equipment which must be maintained at a stable operating temperature at all times. Typical applications include Crane Cabins, Data Loggers, Analyzer Buildings and Portable Laboratories.

Adjustments:

- Power On & Off

- °C or °F Temperature Scale

- Heating Differential Set Point *

- Cooling Temperature Set Point

- Manual or Automatic Fan Operation

- Low & High Room Temperature Alarms

Status Displays:

- Room Temperature

- Unit Operating Status

- Blower & Compressor Status

- Cooling Temperature Set Point

- Heating Set Point, Defrost Cycle & Reversing Valve Status *

Alarm Displays:

- Flashing Red Screen

- Common Trouble Status

- Time Stamped Alarm Log

- Low & High Room Temperatures

- Low & High Refrigerant Pressures

Programmable Alarm Contact:

One (1) Contact rated at 2 Amps, 24 VDC or 24-240 VAC, with a Programmable Open (fail-safe) or Close to Alarm Action, to indicate Low or High Room Temperatures & Refrigerant Pressures.

* Provided with Smart Pump™ Controls

Bebco Model RAC and RHP Roof Mount Unit Smart Cool™ and Smart Pump™ Control Interfaces provide advanced command and diagnostics features. The home screens provide on/off control, manual (continuous) or automatic fan control and compressor, heating and defrost status. The temperature scale screen allows selection of Celsius or Fahrenheit scales and Heat Pump Units will also feature a heating differential temperature setpoint. The room temperature alarm setting screen provides low and high room temperature alarm setpoint adjustment and an option to open or close the alarm contacts upon an alarm event.

The control input and output screens provide real-time diagnostics. This intuitive information is backed up by a time stamped alarm event log on the next screen. Finally, regardless of the displayed screen, it will flash red upon an alarm event. The flashing red screen is very noticeable, and is cleared by touching the screen.

Bebco Smart Cool™ and Smart Pump™ Controls provide full control of room temperature and high and low room temperature alarms, along with diagnostics, screen alarms and remote device alarm contacts. These controls are therefore ideal for buildings or rooms that are critical to refinery, offshore rig or chemical manufacturing facility operations.

These units are suitable for any building or room located within a Class I, Division 2, Group A-D Hazardous Area, and due to their integrity as a fully listed hazardous location climate control unit, may operate continuously, regardless of whether pressurization, emergency ventilation or other protection systems are installed, utilized or functional.

Alarm Contacts & Emergency Shutdown Circuit

– Smart Cool™ and Smart Pump™ Control safety features for critical applications

UNIT FAULT & ROOM TEMPERATURE ALARM CONTACTS

- Indicates unit fault due to high or low refrigerant pressures

- Also indicates excessively high and low room temperatures

- Select from normally open or normally closed contact settings

- Contacts rated for up to 240 VAC at 10 Amps, maximum

See our fully compatible alarm beacons and horns on our Unit Accessories Page to complete your installation…

To utilize this option, select preferred contact action and connect wiring to the alarm contact extension wires located in the ceiling grille area.

This option activates your alarm system or device upon unit fault and low or high room temperatures!

EMERGENCY SHUTDOWN CIRCUIT

- Provides a means to deactivate your unit remotely

- Requires a dry closed contact to maintain unit operation

- 24 VDC milliamp voltage sensing circuit requires no shielding

To utilize this option, connect wiring to the emergency shutdown circuit extension wires located in the ceiling grille area.

This option enables remote unit shutdown using any quantity of normally closed contacts wired in series as a fall-safe circuit.

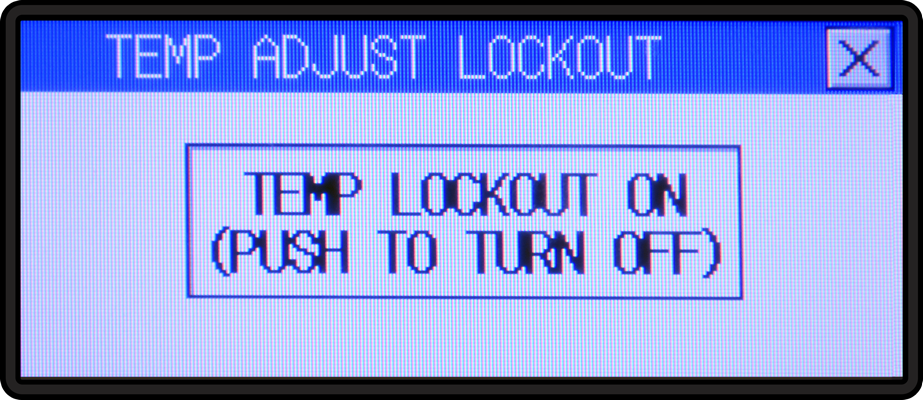

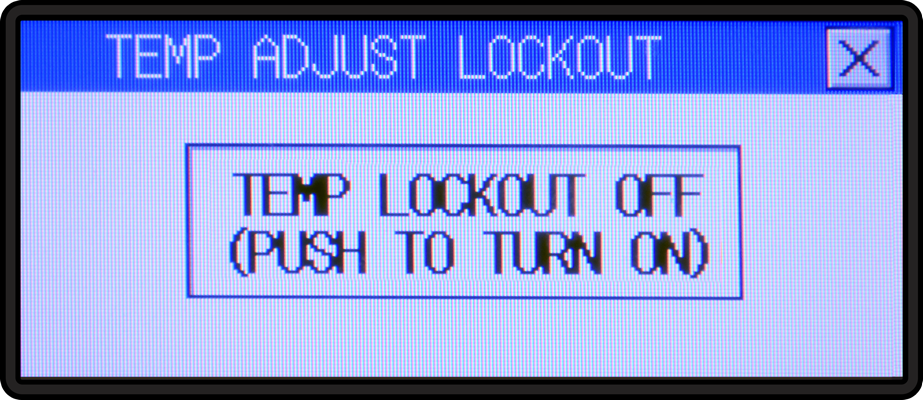

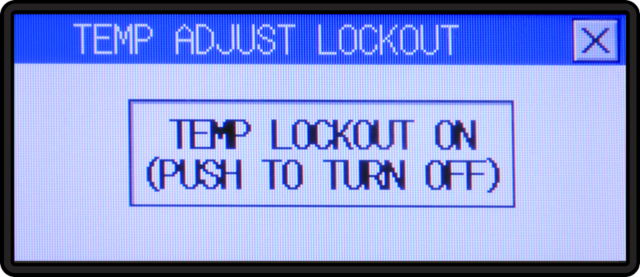

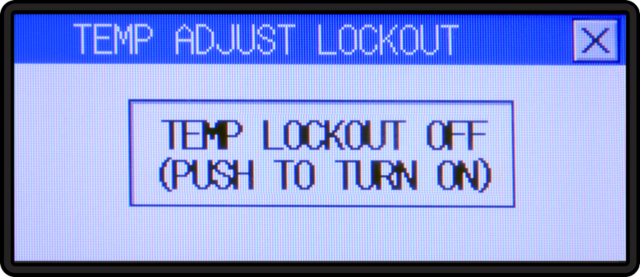

Room Temperature Setpoint Adjustment Lockout Options

– Limits Room Temperature Adjustment to Authorized Personnel

As an optional feature, Bebco offers all Model RAC Air Conditioner and RHP Heat Pump Unit Controls with Room Temperature Setpoint Lockouts to prevent unauthorize or tampering.

Please help us keep this knowledge confidential!

The lockout mechanism for Basic, Eco Cool™ or Eco Pump™ Controls may be activated or deactivated on the Digital Control Panel at any time by authorized personnel who have the knowledge to use it.

The lockout mechanism for Smart Cool™ and Smart Pump™ Controls is embedded in our Touch Screen Controller programs, and may be discreetly activated or deactivated by authorized personnel who have the knowledge to use it.

This feature is intended to prevent unwarranted or unauthorized tampering and for special applications that demand precise room temperature control. As one example, a lockout may be essential for an analyzer building to maintain a specific temperature range that ensures proper analyzer operation and output data accuracy.

Refrigerant System Coil & Tubing Coatings

– Significantly extends refrigerant system lifespan in mild to highly corrosive environments

-

Total Coating by exclusive extraction and application process

-

5 Year Warranty (requires proof of routine preventive maintenance)

-

Critical for On-Shore Water Treatment and Corrosive Chemical Plants

-

Essential for Offshore Rigs and Near Shore Facilities

As an option, Bebco coats both coils and all refrigerant tubing of Roof Mount Units with Heresite® ES-600 Coil Coating, to fully protect the the refrigerant system.

To ensure the highest level of protection and coating adhesion, the coils and tubing are first removed from the chassis and carefully cleaned in accordance with the coating manufacturer’s requirements prior to coating application. Selecting this vital option will provide protection against mild, moderate or extremely corrosive environments, whether exposure duration is considered to be intermittent, prolonged or continuous.

Bebco applies Heresite ® ES-600 Epoxy-Silane Coatings at a dry film thickness of 1.0-1.5 mils, to provide exceptional resistance to harsh solvents including acetone, in accordance with ASTM-D5402.

This coating also achieves compliance to ASTM B117 and ISO 12944-9 testing to pass 3,500 hours of salt spray and 4,200 hours of cyclic corrosion for off-shore facilities, with an ASTM-D3363 hardness rating of 2H-4H.

Need greater corrosion resistance?

Call now to ask about our Heresite P-413 Total Coating Process!

Select our coil and tube coatings to extend your refrigerant system lifespan!

Cover & Chassis Finishes

– Significantly extends Unit lifespan in mild to highly corrosive environments

-

Sprayed or Powder Coated Application

-

Urethane, Epoxy or Custom Finishes

-

Critical for Water Treatment Facilities and Corrosive Chemical Plants

-

Essential for Offshore Rigs and Marine Loading Docks

At a minimum, our CS and CX Style stainless steel covers feature a 2B brushed finish and all CS and CX, PS and PX Style stainless steel chassis feature an ungrained natural finish. However, to enhance corrosion resistance, all stainless steel covers and chassis are offered with advanced industrial coatings.

You may select either a white or grey sprayed urethane or resilient powder coated finish, or if you prefer, you may select a custom finish in any color of your choice!

Our advanced cover and chassis finish options are primarily intended for our durable stainless steel covers and chassis, but may also be applied to EC Style chassis to enhance their corrosion resistance.

This wide range of finish options addresses passive to severely corrosive environments and a custom color and finish may be selected to match a building paint scheme.

| N | 2B Case Finish (for CS & CX Case Style only) |

| G | ANSI 61 Gray Sprayed Urethane |

| S | White Sprayed Urethane |

| T | ANSI 61 Gray Epoxy Powder Coated |

| P | White Epoxy Powder Coated |

| U | Custom Finish |

| X | Excluded (for EC Case Style Only) |