Epoxy Coated & Stainless Steel Window Mount Air Conditioners & Heat Pumps

DRAWINGS & SpecIFICATIONS

- PDF, CAD & STEP Drawings

- Documentation

- Performance Ratings

- Power Requirements

- Dimensions & Weights

- Operating Temperatures

- Clearance Requirements

- Component Material Specs

Bebco provides drawings and complete specifications to meet your needs!

Please note this information is for reference only!

Contact a Bebco Sales Associate for the most accurate information.

We make it easy for you to integrate our products into your designs, and make sure our products comply with all requirements!

Please contact us for technical assistance and other drawing file formats or specifications if needed to satisfy your engineering and design requirements…

PDF, CAD & SOLIDWORKS DRAWINGS

Click any item to learn more, as subject to change without notice…

SPECIFICATIONS

Click any item to learn more, as subject to change without notice…

Complete documentation is provided with each Unit, to make installation fast and easy!

Please contact a Bebco Sales Associate to receive advanced copies of our installation, operation and maintenance manual.

- One (1) Full Color Installation, Operation & Maintenance Manual

- One (1) Quality Control Inspection Report w/ Performance & Test Results

- One (1) Product Registration Form (essential for extended warranty terms)

- One (1) Electrical Wiring Diagram.

Additional Manuals and Wiring Diagrams are available upon request.

Please contact a Bebco Sales Associate for more information.

The following chart lists measured data that constitutes a maximum level or average measurement of performance.

Please contact a Bebco Sales Associate for the most accurate information available.

Model TAC Air Conditioner Units

| Model Number | BTUH Rating | Maximum CFM | EER / CEER Rating | Nominal BTUH Cooling | Nominal BTUH Heating | Max Db | Recommended Sq Ft Conditioning |

| TAC-090 | 9,000 | 280 | 11 / 10.9 | 9K | 8.5K / 10.7K* | 54 | 350-450 |

| TAC-120 | 12,000 | 280 | 11 / 10.9 | 12K | 8.5K / 10.7K* | 55 | 450-550 |

| TAC-140 | 14,000 | 300 | 9.3 / n/a | 14K | n/a / 10.6K* | 61 | 550-700 |

| TAC-150 | 15,000 | 371 | 11.9 / 11.8 | 15K | - | 65 | 550-800 |

| TAC-180 | 18,000 | 360 | 11.8 / 11.8 | 18K | - | 60 | 700-1000 |

| TAC-250 | 25,000 | 523 | 10.3 / 10.3 | 25K | - | 63 | 1000-1500 |

| TAC-280 | 28,000 | 523 | 9.0 / 8.9 | 28K | - | 63 | 1500-2000 |

*Nominal Electric Heat in Units w/ Basic, Eco Cool™ & Eco Pump™ Controls

Model THP Heat Pump Units

| Model Number | BTUH Rating | Maximum CFM | EER / CEER Rating | Nominal BTUH Cooling | Nominal BTUH Heating | Max Db | Recommended Sq Ft Conditioning |

| THP-090 | 9,000 | 280 | 9.9 / 9.8 | 9K | 7.2K / 7.5K | 69 | 350-450 |

| THP-120 | 12,000 | 265 | 9.9 / 9.8 | 12K | 9.9K / 10.2K | 72 | 450-550 |

| THP-180 | 18,000 | 541 | 9.9 / 9.8 | 18K | 14K / 14.3K | 74 | 700-1000 |

Nominal Electric Heat in Units w/ Basic, Eco Cool™ & Eco Pump™ Controls

THP-090: 8.5K / 10.7K THP 120: 9.4K / 12.2K THP 180: 10.3K / 12.5K

This data constitutes a maximum or average measurement of performance.

Dual BTUH listings for Nominal BTUH Heating reflects 208 vs. 230 VAC Operating Voltages.

As listed, some TAC & THP Units with Basic and Eco Controls feature electrical heating elements.

Recommended Square Foot Conditioning represents the minimum to maximum square footage of space each unit can effectively condition, based upon an 8′ ceiling height.

Consider use of larger units or multiple units for significant heat loads, separate rooms, larger spaces and higher ceilings.

All information above is subject to change without notice and is provided for reference only.

Consult a Bebco Sales Associate for specific unit information at time of inquiry or order.

The following chart lists the average power consumption of Model TAC and THP Units in Cooling and Heating Cycles.

Please contact a Bebco Sales Associate for more information or assistance.

Model TAC Air Conditioner Units

Operating Voltage | 120 VAC 1Ø 60 Hertz | 208 VAC 1Ø 60 Hertz | 230 VAC 1Ø 60 Hertz |

|||

Model Number | BTUH Rating | Cooling Cycle | Cooling Cycle | Heating Cycle | Cooling Cycle | Heating Cycle |

TAC-090 | 9,000 | - | 4.0 | - | 3.4 | - |

TAC-120 | 12,000 | - | 4.9 | - | 4.5 | - |

TAC-140 | 14,000 | - | - | - | 15 | - |

TAC-150 | 15,000 | 11.9 | - | - | - | - |

TAC-180 | 18,000 | - | 7.5 | - | 7.0 | - |

TAC-250 | 25,000 | - | 11.8 | - | 10.8 | - |

TAC-280 | 28,000 | - | 15.0 | - | 13.8 | - |

Model THP Heat Pump Units

Operating Voltage | 120 VAC 1Ø 60 Hertz | 208 VAC 1Ø 60 Hertz | 230 VAC 1Ø 60 Hertz |

|||

Model Number | BTUH Rating | Cooling Cycle | Heating Cycle | Cooling Cycle | Heating Cycle | Cooling Cycle |

THP-090 | 9,000 | - | 4.2 | 3.8 | 3.9 | 3.5 |

THP-120 | 12,000 | - | 5.9 | 5.6 | 5.6 | 5.1 |

THP-180 | 18,000 | - | 9.0 | 8.8 | 8.5 | 8.3 |

All information above is subject to change without notice and is provided for reference only.

Consult a Bebco Sales Associate for specific unit information at time of inquiry or order.

The following chart provides all unit dimensions and weights based on the unit size and voltage, along with factors that affect these specifications.

Please use this guide to ensure our product’s compatibility with your specific application!

Model TAC Air Conditioner Units

| Model Number | BTUH Rating | Unit Height | Unit Width | Unit Depth | Unit Weight |

| TAC-090 | 9,000 | 15.375" | 22.6" | 26.75" | 108 lbs |

| TAC-120 | 12,000 | 15.375" | 22.6" | 26.75" | 111 lbs. |

| TAC-140 | 14,000 | 14.5" | 24.2" | 20.3" | 78 lbs |

| TAC-150 | 15,000 | 17.94" | 25.4" | 23.6" | 106 lbs. |

| TAC-180 | 18,000 | 17.94" | 23.625" | 25.44" | 129 lbs |

| TAC-250 | 25,000 | 18.6" | 26.5" | 26.5" | 151 lbs. |

| TAC-280 | 28,000 | 18.6" | 26.5" | 26.5" | 156 lbs. |

Model THP Heat Pump Units

| Model Number | BTUH Rating | Unit Height | Unit Width | Unit Depth | Unit Weight |

| THP-090 | 9,000 | 15.375" | 22.6" | 26.75" | 108 lbs |

| THP-120 | 12,000 | 15.375" | 22.6" | 23.5" | 110 lbs. |

| THP-180 | 18,000 | 17" | 25.85" | 30.375" | 159 lbs |

All information above is subject to change without notice and is provided for reference only.

Consult a Bebco Sales Associate for specific unit information at time of inquiry or order.

This chart provides an overview of minimum and maximum operating temperatures to ensure our unit is compatible with your specific application.

Please contact a Bebco Sales Associate for applications exceeding the ranges stated below.

| Model Configuration | Operating Mode | Minimum Temperature | Maximum Temperature |

| TAC | Cooling | 60°F | 120°F |

| TAC | Fan Only | -40°F | 120°F |

| THP | Cooling | 60°F | 120°F |

| THP | Heating | 40°F | 120°F |

Operating Units within the posted Temperature Ranges will insure optimum unit performance, year-round.

Please contact a Bebco Sales Associate for more information.

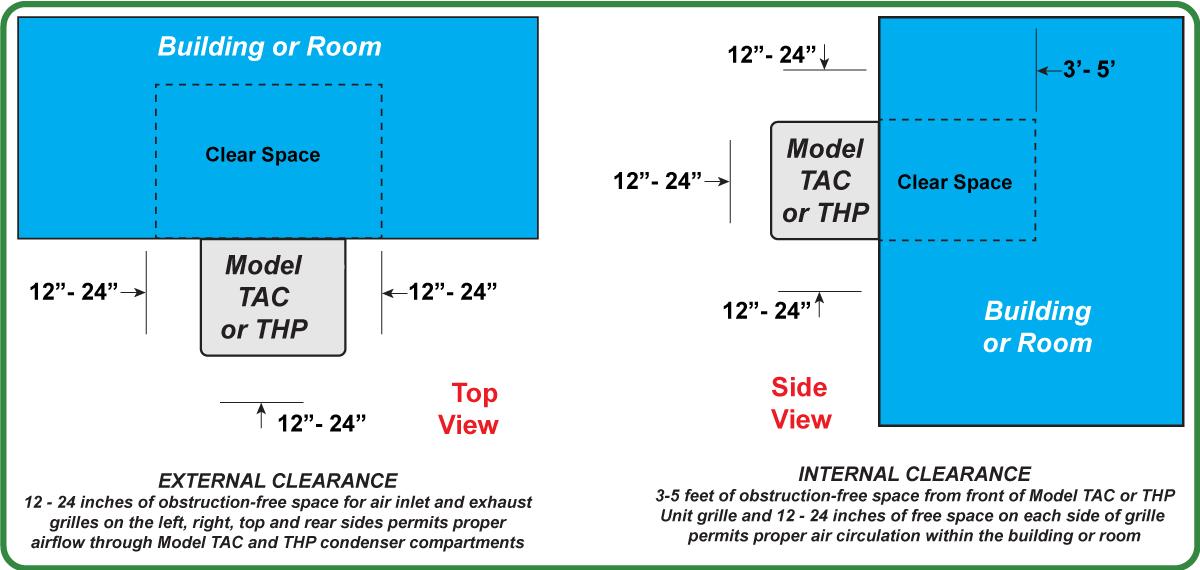

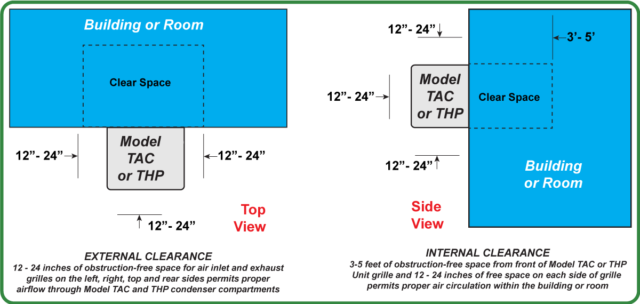

The following data and diagram indicate “free space” clearances around our units that are essential to proper operation.

Please contact a Bebco Sales Associate for more information.

BEST PRACTICES

Provide minimum external clearances on the left and right sides and top side of a Model TAC or THP Unit for inlet air and on the rear side of a Unit for exhaust air that is passing through the condenser compartment.

Provide minimum internal clearance for recirculating airflow within the room or building.

Exterior Clearances

Twelve to Twenty-Four Inches (12″-24″) from the left, right, top and rear exterior sides of Model TAC & THP Units

Interior Clearances

Three to Five Feet (3′-5′) from face of interior Grille and One to Two Feet (1′-2′) to each side of Grille of Model TAC & THP Units

Click image to enlarge

Model TAC & THP Clearance Requirements

The absence of external airflow obstructions is extremely critical to ensure unimpeded air flow through Model TAC & THP Hazardous Location Through Wall & Window Mount Air Conditioner condenser compartments. Internal airflow obstructions must also be avoided to ensure proper air circulation within your building or room.

Please follow these simple guidelines to ensure maximum efficiency!

Minimum clearances are critical to ensure proper unit operation!

Reliable, industrial-grade materials and components guarantee optimal unit performance in the harshest industrial environments!

Please contact a Bebco Sales Associate for more information.

| EC Style Case & Chassis: | 22 & 20 Gauge Epoxy Coated Steel |

| EC Style Brackets & Covers | 16-22 Gauge Galvanized Steel |

| CS Style Case & Chassis: | 16 Gauge 304 Grade Stainless Steel |

| CS Style Brackets & Covers | 16-22 Gauge 304 Stainless Steel |

| CX Style Case & Chassis: | 16 Gauge 316 Grade Stainless Steel |

| CX Style Brackets & Covers | 16-22 Gauge 316 Stainless Steel |

| Evaporator Compartment Insulation: | Molded Polystyrene |

| Case Gaskets: | Neoprene & Butyl Rubber |

| Refrigerant Coils: | Copper Tubing w/ Aluminum Fins |

| Refrigerant Lines: | Copper Tubing |

| Refrigerant Pressure Switches: | Brass & Plastic w/ SS Switch |

| Refrigerant Service Ports: | Brass |

| Tubing Insulation: | ASTM E-84 Elastomeric |

| Condensation Drains: | Polyurethane & Nylon |

| Condenser & Evaporator Fan & Blower Motors: | Steel Housing |

| Condenser Unit Fan Blade: | Plastic |

| Evaporator Unit Blower Wheel: | Plastic |

| Compressor Case: | Seal Welded Carbon Steel |

| Compressor Construction: | Scroll, Rotary or Reciprocating Style |

| Nameplates: | Reverse Print Lexan® w/ VHB™ Adhesive |

| Fasteners: | Zinc Plated Steel and/or Stainless Steel |

| Air Filters: | Washable Polypropylene |

| EC Style Case Standard Finishes: | Baked Enamel |

| CS & CX Style Case Standard Finishes: | 2B Brushed |

| EC, CS & CS Style Case Optional Finishes: | ANSI 61 Gray Sprayed Urethane White Sprayed Urethane ANSI 61 Gray Epoxy Powder Coated White Epoxy Powder Coated |

| Motor & Compressor Finishes: | Epoxy Paint |

| Refrigerant Type: | R410a |

| Optional Coil & Refrigerant Tube Coatings: | Heresite® ES-600 |

Pressure Switches are included with Units featuring Smart Cool™ & Smart Pump™ Controls

Lexan® is a registered trademark of the General Electric Corporation

VHB™ is a trademark of the 3M Corporation

Heresite® is a registered trademark of Heresite Protective Coatings